What is Work Measurement? Methods, Process & How It Works

Work measurement is a quality process determining how long it takes to do a task under regular working conditions. It is commonly used in business to enhance work efficiency , reduce time wasted , and create reasonable correctness standards for performance.

Businesses could enhance their productivity as well as employee satisfaction through the use of various work measurement procedures. This process is crucial in bringing in workforce planning, labor cost containment, and operational efficiency .

Let’s uncover how work measurement is powerful that can transform the way work gets done.

What Is Work Measurement?

Work measurement analyses tasks to find the standard time needed to finish them using a standard procedure under typical situations.

The primary purpose of work measurement is to set up time standards to control performance, better define planning, and have a basis of fairness in workload distribution . It delivers a fact-based framework for scheduling, budgeting, and workforce management.

Importance of Work Measurement

- Honest with its time frame of completion of the task

- Assists in removing the slow progress

- Supports employee training and development

- Assists in performance benchmarking and incentive planning

- Improves resourcing and job scheduling

According to a study by McKinsey, companies that actively measure and optimize workflows see up to 25% gains in workforce productivity .

What Are the Main Objectives of Work Measurement?

Here are the main objectives of work measurement, which include:

- Creating Basic Times: Determine the expected time for each task under normal conditions.

- Increase Efficiency: Uncover and delete spamming steps that waste your time.

- Reduce Scheduling Mistakes: Schedule resources and shifts more precisely.

- Manage Labor Costs: Minimize unnecessary labour costs by increasing task efficiency.

- Fair Load Assignment: Spread the chores according to average job durations.

- Creating Incentive Plans: Build fair reward systems on reliable data.

- Decision Support: Concrete data basis for optimization of processes and investment planning

According to data- “Organizations have seen as much as a 30% increase in productivity and 25–30% reduction in operational costs by applying process optimization and continuous improvement techniques.”

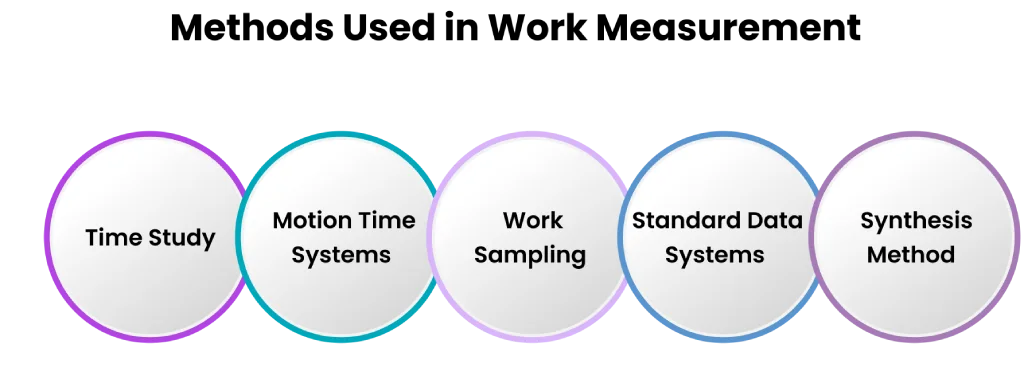

What Are Some Methods Used in Work Measurement?

There are several ways to identify the commonly used work measurement methods, depending on their job. Below are the primary techniques used across industries:

1. Time Study (Stopwatch Technique)

A trained analyst uses a stopwatch to measure how long it takes to complete a task. This method works best for simple, repetitive jobs in factories or production settings.

2. Predetermined Motion Time Systems (PMTS)

It is achieved using predefined time values for the elementary movements, like reach, move, or assemble. A prominent example of a PMTS is Method Time Measurement (MTM). It is very accurate and great to use during manual and physical jobs where consistency is the key.

3. Work Sampling

Random work samples are observed and recorded to estimate the time spent on different activities. It is less expensive and recommended for non-repeating jobs like maintenance and supervisory.

4. Standard Data Systems

This method uses previous analysis or job study to provide the source of the time values. It is effective for the same type of task and does not waste time on direct observation for faster implementation.

5. Synthesis Method

The synthesis method implies the creation of standard times based on observed facts about basic elements of work. This method is especially useful when direct observation is difficult, such as in complex or indirect activities.

Deloitte found that organizations that closely track employee task time — using techniques like stopwatch studies or time-data analysis — can reduce hourly labor costs by 0.5% to 2%.

This helps improve pricing accuracy and reduce unnecessary expenses.

What Is the Standard Procedure for Conducting Work Measurement?

Follow this step-by-step process to implement work measurement in any organization successfully:

Step 1: Select the Task

First, determine what task or process you want to measure. Choose the most frequent and productive jobs.

Step 2: Understand the Task

Divide the task assignment into smaller segments or parts. Separating elements allows time to be recorded accurately, and time spent can be pinpointed for improvement.

Step 3: Select the Best Approach

Pick those work measurement methods relevant to the type of job. Put time study in for all work of repetition. For non-repetitive or non-homogeneous work, use work sampling or PMTS.

Step 4: Record Observations

Make detailed timings. Do this in real time or from records to determine how long the key component of the task takes.

Step 5: Determine basic and normal time

To regulate time of sighting in regard to the efficiency and permittances of fatigue , reliefs and delays. It provides the baseline time you will have to perform the function.

Step 6: Apply and Monitor

Apply the established standard time for planning, workforce estimation, and evaluation. Review regularly and adjust as processes and conditions change.

What Are the Common Mistakes Which Should Be Avoided in Work Measurement?

To avoid common mistakes and ensure effective and constructive work measurement:

- Opting for the wrong approach for the type of job.

- Ignoring the allowances of rest, weariness, and accidents

- Dissatisfying outcomes because of a fewer number of observations

- Untrained or prejudiced observers in time studies

- Failing to revise time standards in light of process changes

- Ignoring communication with employees, who may resist