Home / N / Non-Productive Time

What Is Non-Productive Time? Importance, Examples, Reduction Tips & How to Calculate

All organizations expect their employees and machines to have downtime or not operate properly at some point, but some organizations consider these moments, although sometimes overlooked, to have an impact on efficiency, output, and even profits.

Non-productive time (NPT) is an important measure for highlighting wasted time and identifying areas for improvement in the workplace, and how to calculate NPT, track NPT, and take corrective actions is important to understand in any industry, from manufacturing to tech startups. Even a small reduction in NPT can generate large gains. A McKinsey study showed that companies that measured and tracked NPT can improve productivity 15–20% over a sustained period of time.

In this article, we explain what non-productive time is, examine examples of non-productive time, describe ways to track and calculate non-productive time, and provide tips for reducing non-productive time as a means of improving performance.

What Is Non-Productive Time?

Non-productive time (NPT) is defined as all occurrences during work hours when employees, equipment, or other resources are not engaged in productive activity. NPT may consist of idle time, delays, wait time, and interruptions that do not contribute to adding value to output.

Impact on Business Performance

Non-productive time has impacts beyond workflow and can also affect revenue, morale, and client satisfaction. NPT can have hidden identities that impact overall performance and create bottlenecks if not improved.

In the case of service industries, if employees are idle in a busy environment, billable time is lost. If machinery is waiting for parts or materials in a manufacturing environment, it disrupts production schedules and delays deliveries.

Mapping NPT allows managers to identify inefficient operations. Data collected about NPT gives managers information that can assist them in restructuring schedules, automating repetitive tasks, or eliminating unnecessary meetings. Reducing non-productive time increases productivity and profitability.

Companies that simply employ a time-tracking system and monitor NPT will discover they can increase overall output by as much as 5 percent for the same cost.

What Are the Main Causes of Non-Productive Time?

Recognizing the reasons for non-productive time (NPT) is the first step toward addressing it. Some areas of the source are commonly used by businesses.

- Poor Planning: When individuals do not have specific timelines or allocations for resources, there can be delays and confusion.

- Pending Action: Workers are in a waiting state because they are waiting for resource allocation, approvals, or input from another person to do their work.

- Downtime: Technical glitches or software outages that halt productive work.

- Inefficient Meetings: Meetings that last too long do not follow the intended agenda, or do not add value.

- Lack of Knowledge: Workers do not know how to perform tasks efficiently.

- Miscommunication: Tasks that are duplicated or must be redone because of unclear instructions or misinformation.

By identifying these sources, organizations can direct their improvement efforts and redesign their processes to make the best of their valuable time.

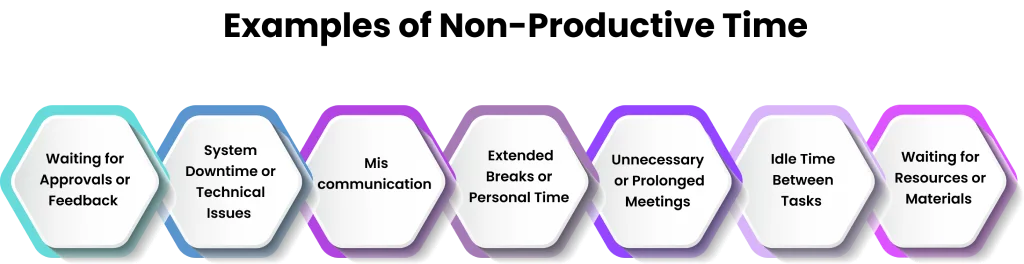

What Are the Examples of Non-Productive Time?

Non-productive time, also NPT, is defined as any period of time during the workday when employees, machines, or other resources are not creating valuable output. These moments may feel insignificant, but they soon add up and can have a tremendously impactful influence on productivity!

Here are some common examples of unproductive time across several industries:

1. Waiting for Approvals or Feedback

Sometimes employees wait for something to get the ball rolling in the next step of a project: feedback, approvals from a manager, etc., and other times, it just sits there when it isn't moving for whatever reason. This is idle, non-productive time, but there are definitely circumstances to alleviate this idle time with faster communication and workflow design more clearly at the groundbreaking planning phase.

2. System Downtime or Technical Issues

What is common is that workers can't access something they need, whether that's tools they use more so than people professionals, or websites, platforms, or other access points, and their productivity drops. This is common in technology or remote workspaces, and often, if you see people waiting for downtimes, you will see people waiting long times for things to become accessible due to all sorts of issues: systems crashing, glitches, or internet connection limitations.

3. Unnecessary or Prolonged Meetings

Not all meetings are productive. Employees are wasting time when they are in long, structured meetings, without clear deliverables, especially when it disrupts the workers' flow of deep work.

4. Waiting for Resources or Materials

Depending on the industry (manufacturing, construction, etc), there is plenty of waiting for raw materials, tools, parts, etc. Non-productive time like this can cause unplanned delays to workflow or deliveries and can even cause lost productivity to other workers because they simply couldn't do a job without the parts.

5. Rework Due to Miscommunication

Oftentimes employees will be required to redo work either because it was misunderstood or poorly communicated. This can be a huge waste of time and resources, especially time that was intended to be productive and got turned into unproductive time.

6. Extended Breaks or Personal Time

Breaks- we all need them. However, consistently going longer than the allowed breaks or spending worktime on personal matters actually detracts from effective working time.

7. Idle Time Between Tasks

There are sometimes short periods of downtime when an employee is going from finishing a task and waiting to receive the next assignment to work on. Though this is relatively quick, it is still unproductive time.

Recognizing each of the items can be important for business leaders and their HR teams. Once they are aware and engaged, the organization can begin to monitor and reduce those gaps so they can improve overall productivity and operations.

How to Track Non-Productive Time?

Monitoring any non-productive time (NPT) will involve a combination of tools, data collecting, and watching how things are done:

1. Use Time Tracking Software

Software such as Time Champ can automatically track task duration, idle time, and system-related activity.

2. Conduct Time Audits

Monitor how people use their time during the day and report where time loss happens.

3. Use Daily Logs or Timesheets

Employees record what they do daily, with detailed end-of-day entries to highlight idle times.

4. Review Meeting Reports

Report the number, duration of meetings, with an indication of impact on the delivery of work.

5. Analyze System Logs

IT teams can measure server or software downtime by backend logs to find non-productive time gaps.

Measurement must not be intrusive and use data analysis to encourage employee compliance and reporting honesty.

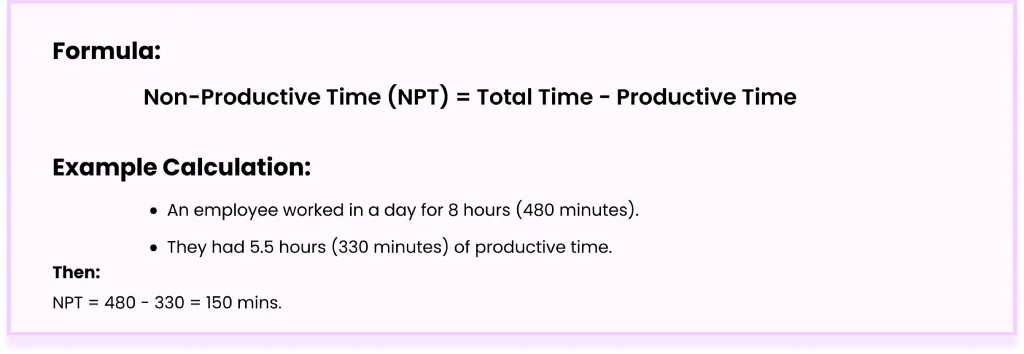

How to Calculate Non-Productive Time (NPT)

Knowing how to calculate non-productive time means businesses can quantify lost time and identify opportunities for improvement.

Formula:

Non-Productive Time (NPT) = Total Time - Productive Time

Where:

- Total Time = Total potential working hours in any day or shift.

- Productive Time = Time spent working on projects that are directly tied to output.

Example Calculation:

Let’s say:

- An employee worked in a day for 8 hours (480 minutes).

- They had 5.5 hours (330 minutes) of productive time.

Then:

NPT = 480 - 330 = 150 mins.

In which case, the employee’s NPT for the day was 150 mins.

What Are the Best Tips to Reduce Non-Productive Time?

Lowering NPT requires a combination of process improvement, effective communication, and tools.

Top Tips to Reduce Non-Productive Time:

- Automate Repetitive Tasks: Utilize tools to manage any work that includes data entry, approval, or notifications.

- Strengthen Training: Provide employees with the correct knowledge and the right tools from the beginning.

- Upgrade Communication Tools: Reduce threaded emails by moving to project management tools.

- Refine Your Priorities: Minimize confusion by seeing how daily activities relate to long-term strategic goals.

- Eliminate Unproductive Meetings: Instead of meetings, replace them with a few minutes for a stand-up or update.

How Is Non-Productive Time Managed Across Different Industries?

- Manufacturing: Apply lean practices to minimize machine downtime and improve the supply chain.

- Healthcare: Automate appointment scheduling and documentation to minimize staff downtime.

- IT/Software: Use agile workflows to prevent developers from being stalled waiting for feedback from others.

- Customer Service: Monitor agent idle time, and leverage scheduling to prepare for demand surges.

Industry-specific strategies are important methods to eliminate idle time without overworking employees or decreasing quality.

What Is the Difference Between Productive Time and Non-Productive Time?

Understanding the difference helps in proper performance evaluation and planning.

| Aspect | Productive Time | Non-Productive Time |

|---|

By separating the two, organizations can accurately measure efficiency and take steps to optimize work hours.